Charles Miller is a veteran bike enthusiast with over 12 years of experience dealing with bikes as a mechanic. Despite immense love and expertise for...

Peeling back the layers of an electric bike battery is like opening a Pandora's box of high-tech materials. We're talking about sophisticated elements such as lithium-ion, lead-acid, nickel-cadmium, and lithium polymer. Each of these has its own particular strengths and weaknesses, balancing factors like weight, capacity, cost, and charging time.

It's a captivating world that's both highly technical and surprisingly practical. And why should we care about these seemingly obscure details? Well, understanding what's inside our e-bike batteries can help us make more informed choices about our rides, optimizing for range, weight, and cost.

So, shall we pull back the curtain and shed some light on this intriguing subject?

Key Takeaways

- Electric bike batteries are commonly made of various types of materials, including lithium-ion, lead-acid, nickel-cadmium, lithium polymer, and graphite.

- Lithium-ion batteries are the most popular choice due to their high capacity, rapid charging, and durability. They consist of elements such as cobalt, manganese, and nickel.

- Lead-acid batteries, although affordable, have drawbacks such as weight and limited cycle life. They require regular maintenance and are composed of lead plates submerged in a sulfuric acid solution.

- Nickel-cadmium batteries are lightweight and have speedy recharge times but have a shorter life expectancy and are prone to memory effect. They consist of nickel and cadmium electrodes immersed in a potassium hydroxide solution.

- It is important to understand the working principle of lithium-ion batteries, where movement of lithium ions between electrodes allows for charging and discharging. Battery management systems (BMS) protect the cells from overcharging or excessive draining.

The Basics of E-bike Batteries

Diving into the basics of E-bike batteries, it's essential to understand that lithium-ion batteries, due to their long shelf life, durability, and quick charging times, are the most popular choice on the market, despite alternatives like lead-acid, Nickel-Cadmium, Lithium Polymer, and graphite batteries. As a community of electric bicycle enthusiasts, we appreciate the favorable weight optimization and energy efficiency of lithium battery cells.

However, it's worth examining the alternatives. Lead-acid batteries, though less popular, are robust and inexpensive. Their main drawbacks are their weight and maintenance requirements. Nickel-Cadmium batteries offer lightness and speedy recharge times, but suffer from a short life expectancy and the notorious memory effect.

The Lithium Polymer option presents a lightweight, heat-resistant solution with high capacity, but with a higher price tag. Slowly but surely, they're carving out a niche in the E-bike batteries market. Lastly, graphite batteries, boasting high energy storage, low reactivity, and a long life expectancy, present an exciting prospect for the future.

Understanding the charge and discharge characteristics and the capacity of each type of battery helps us make informed decisions for our electric bicycles. It's a complex world, but together, we're mastering it.

Lead-acid Battery Composition

Peeling back the layers of a lead-acid battery, we find a core made of lead plates submerged in a sulfuric acid solution, a composition that's both reliable and affordable. This is one of the most common types of batteries used by e-bike manufacturers, primarily due to their cost-effectiveness.

The battery composition is quite complex. The positive plate contains lead dioxide, while the negative plate is made of sponge lead. These lead plates act as electrodes and are immersed in an electrolyte solution, typically sulfuric acid diluted with water. The interaction between these components generates the electrical energy that powers electric bikes.

Lead-acid batteries, however, aren't without drawbacks. Their weight and limited cycle life can be a challenge for e-bike manufacturers and users alike. Furthermore, they require regular maintenance due to the nature of their composition. Despite these challenges, their affordability, and ability to provide high current make them a popular choice among various battery types for electric bikes.

As we delve deeper into the world of e-bikes, it's important to understand the intricacies of their power sources. It's the composition and characteristics of these lead-acid batteries that contribute to the overall performance and efficiency of the e-bikes we belong to.

Unpacking Lithium-ion Batteries

As we unpack lithium-ion batteries, we'll first explore their composition, noting elements such as cobalt, manganese, and nickel.

We'll analyze the intricate working principle behind these powerhouses, shedding light on their high capacity, rapid charging, and durability.

Lastly, we'll touch on the latest advancements in lithium-ion technology, focusing on how they continue to reshape the landscape of electric bike batteries.

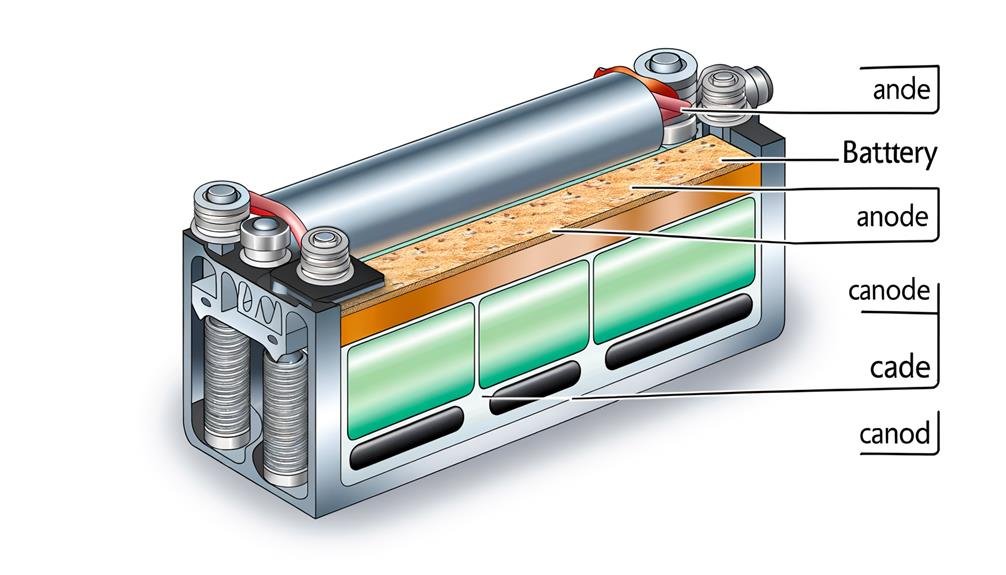

Composition of Lithium-ion Batteries

Within the heart of electric bikes, lithium-ion batteries function, carefully engineered with various formulas such as cobalt and manganese to optimize weight and energy for the best range and longevity. In understanding what electric bike batteries are made of, we often refer to the composition of lithium-ion batteries.

| Battery Type | Main Components |

|---|---|

| LiFePo4 | Lithium, Iron, Phosphate |

| Lead-acid | Lead, Acid |

| Lithium 18650 | Cobalt, Manganese |

These lithium-ion cells are commonly used in e-bike batteries, wired in series for desired voltage and parallel for increased capacity. A crucial part of the lithium-ion battery is the battery management system (BMS), a guardian protecting cells from overcharging or excessive draining. This intricate composition makes electric bike batteries efficient and reliable.

Working Principle Behind Lithium-ion

Delving into the workings of lithium-ion batteries, we find that they operate based on the movement of lithium ions between the positive and negative electrodes during both charging and discharging. This is the working principle behind lithium-ion that powers electric bike batteries.

To help you understand better, let's unpack this:

- During discharging, the positive electrode, made of lithium cobalt oxide, releases lithium ions which move to the graphite-made negative electrode.

- During charging, the process reverses and the ions move back to the positive electrode.

- The electrolyte allows these movements while preventing direct contact between electrodes.

- A separator prevents short circuits, ensuring we can enjoy our electric bikes worry-free.

In essence, it's the dance of lithium ions that makes our electric bike batteries tick!

Lithium-ion Battery Advancements

In the constantly evolving world of e-bikes, advancements in lithium-ion batteries are reshaping our riding experiences, with these power sources now boasting a long shelf life, durability, higher capacities, and faster charging times. We've seen a rise in the use of Lithium Iron Phosphate in battery packs for electric vehicles due to their improved energy capacity and ability to handle frequent charging and discharging.

| Lithium-ion Battery Advancements | ||

|---|---|---|

| 1 | High Energy Capacity | Lithium Iron Phosphate |

| 2 | Fast Charging Times | Battery Pack |

| 3 | Frequent Charging and Discharging | Electric Vehicles |

These advancements in lithium-ion batteries contribute to the greater efficiency, performance, and overall experience of our e-bike rides. Rest assured, we're part of a revolution in personal transportation.

Nickel-Cadmium Battery Structure

We're now shifting our focus to the structure of Nickel-Cadmium (NiCd) batteries.

Their composition includes nickel and cadmium electrodes, with nickel hydroxide as the positive electrode and cadmium hydroxide as the negative, immersed in a potassium hydroxide solution.

The performance and lifespan of these batteries, enclosed by a steel casing, will further be examined in the ensuing discussion.

Composition of NiCd Batteries

Let's unravel the complex structure of Nickel-Cadmium (NiCd) batteries, commonly used in E-bike battery packs. These power sources consist of nickel and cadmium electrodes, separated by an absorbent glass mat, and drenched in a potassium hydroxide electrolyte solution.

To evoke emotion and a sense of belonging, consider the following:

- NiCd batteries house separate cells, each contributing to the overall power output.

- Their robust structure ensures a steady flow of energy to your E-bike.

- Proper care for your battery extends its life and maintains its efficiency.

- Understanding the battery's composition can foster a deeper connection to your E-bike.

Performance and Lifespan

Navigating the intricacies of Nickel-Cadmium battery structure, it's crucial to note that these batteries, while lighter and quicker to recharge, do have a shorter lifespan. A good battery, they're susceptible to memory effects, impacting their performance and lifespan. With regular use and proper maintenance, we can increase the lifespan.

A vital factor is the amount of energy stored in the battery. Watt Hours, representing the energy capacity, should be closely monitored. Charging to around 80% and avoiding extremely low voltages optimizes its lifespan.

For longer life, it's advisable not to fully charge the battery, but to use a reputable charger specifically designed for this type.

Lithium Polymer Battery Components

Diving into the heart of Lithium Polymer batteries, it's critical to understand their unique components that grant them a high-energy capacity and lightweight nature. We'll dissect the lithium polymer battery components, highlighting their distinct roles and advantages.

- Cathode: The cathode, typically made of lithium cobalt oxide, is where lithium ions move during discharge, generating a higher voltage of about 3.7 volts. This is significantly greater than the 1.5 volts produced by conventional batteries.

- Anode: The anode, usually composed of carbon, stores lithium ions during the charge process. It's responsible for the higher capacity of Lithium Polymer batteries.

- Electrolyte: The electrolyte, a lithium salt in an organic solvent, facilitates the movement of lithium ions between the cathode and the anode.

- Separator: The separator, a thin insulating layer, prevents a short circuit between the cathode and anode while permitting ion flow.

These components collectively contribute to a capacity and low weight ratio that's 63% more efficient than other batteries.

As we continue to explore the world of electric bike batteries, it's clear that Lithium Polymer batteries, with their higher voltage and capacity, are pushing the boundaries of what's achievable.

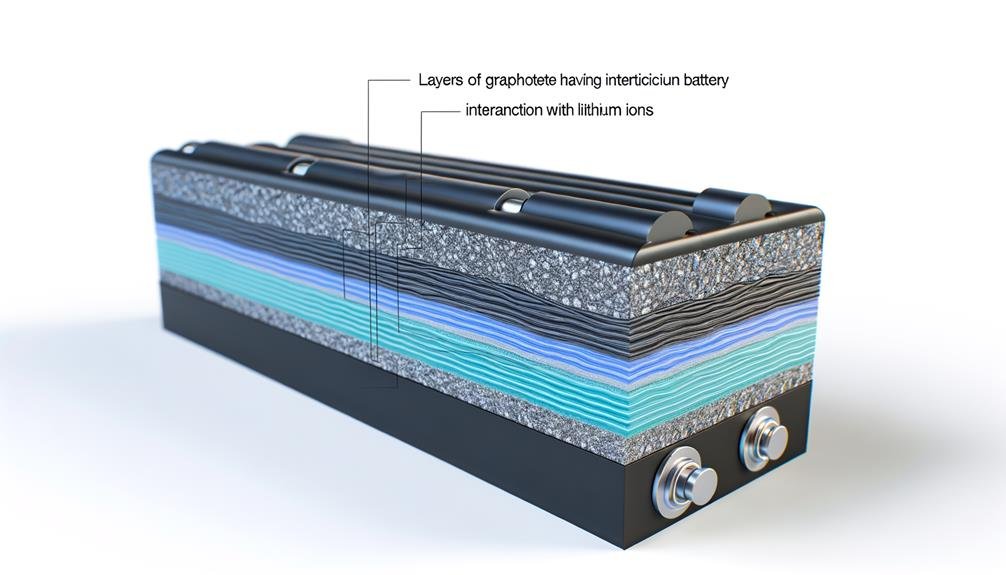

Role of Graphite in Batteries

As we examine the intricacies of electric bike batteries further, we find graphite playing a crucial role in these power systems, especially due to its remarkable properties that enhance energy storage and safety. This component contributes to your e-bike battery delivering more miles per single charge, a crucial aspect considering an e-bike is only as good as its weakest part.

If you're planning to make your own electric bike, understanding the role of graphite can help you choose between different types of e-bike batteries. It's particularly beneficial for lower power applications, where energy efficiency and safety are paramount.

Here's a table to illustrate the role of graphite in batteries:

| Property | Role | Impact on Battery |

|---|---|---|

| Low Reactivity | Enhances Stability | Longer Life Expectancy |

| Low Thermal Conductivity | Resists Heat | Increased Safety |

| High Energy Storage | Efficient Charging/Discharging | High Performance |

| Long Life Expectancy | Ensures Durability | Reliable Power Source |

| Energy Efficiency | Optimizes Capacity | More Miles per Charge |

The Function of Copper in E-bike Batteries

Turning our attention to copper, we find it plays a pivotal role in conducting and transporting electricity within the complex system of e-bike batteries. As a key component, copper ensures that our e-bike batteries function effectively.

Here's why copper is so vital in electric bike batteries:

- Conductivity: Copper is known for its superb electrical conductivity. This enables smooth transmission of electricity within the battery system. Whether your e-bike requires a HUGE battery with much power or a compact one with low power, copper guarantees efficient energy flow.

- Reduced Resistance: The presence of copper minimizes resistance in the battery. This means less energy loss and more power for your e-bike.

- Reliable Interconnections: Copper is used to create reliable battery terminals and interconnections. This ensures uninterrupted energy transfer, so your e-bike never lets you down.

- Enhanced Performance: Copper's conductive properties significantly enhance the performance and reliability of e-bike batteries.

As e-bike enthusiasts, we understand how important it's for our e-bikes to perform at their best. Let's appreciate the function of copper in our e-bike batteries, an unsung hero that keeps our wheels turning.

Frequently Asked Questions

What Are Ebike Batteries Made Of?

We're often asked, "What are e-bike batteries made of?" They're typically constructed of lead-acid, lithium-ion, or nickel-cadmium, each offering different lifespan, safety, and charging methods. Brands and voltage differences also factor into their performance and recycling processes.

Are All Ebike Batteries Lithium Ion?

No, not all e-bike batteries are lithium-ion. While we love their longevity, other types exist. Upgrading batteries requires thought, not just for maintenance, but also disposal, safety precautions, and their eco impact.

What's Inside an Ebike Battery?

We're delving into e-bike batteries, which encompass safety features, charging protocols, and technology to optimize lifespan. Maintenance and understanding environmental impact are vital, as advancements continue to enhance their efficiency and sustainability.

Is It Cheaper to Build Your Own Ebike Battery?

We've crunched the numbers, and yes, DIY costs can be lower. But it's not just about money. You'll need technical assembly knowledge, and there are safety concerns and quality control issues. Sustainability aspects also bear considering.

Conclusion

In conclusion, we've delved into the complex world of e-bike batteries, exploring the intricacies of materials like lead-acid, lithium-ion, nickel-cadmium, and lithium polymer. We've unearthed the essential roles of graphite and copper in these powerhouses.

By understanding these intricacies, we can make informed decisions when selecting our e-bike batteries, balancing factors such as range, weight, and cost.

Ultimately, the material composition of our batteries shapes our e-biking experience.

Charles Miller is a veteran bike enthusiast with over 12 years of experience dealing with bikes as a mechanic. Despite immense love and expertise for his Tacoma, he rides his Trek Ebike more. Anytime you meet him, you’ll either hear him talking about Bikes, or writing about all things bikes and cars on this blog.

More Posts