Charles Miller is a veteran bike enthusiast with over 12 years of experience dealing with bikes as a mechanic. Despite immense love and expertise for...

Did you know that nearly half the electric bikes sold worldwide utilize hub motors?

As an electric bike enthusiast, I find this piece of information quite intriguing. These hub motors are fascinating little pieces of technology, silently propelling us forward with surprising efficiency.

To appreciate their functionality, it's essential to understand how they work. The basics involve the conversion of electrical energy into mechanical energy, but there's much more involved in the process.

What makes these motors tick? Come along and explore this intriguing world of electric bike hubs, and you might just find yourself as captivated by their inner workings as I am.

- Key Takeaways

- Understanding Electric Bike Hubs

- Types of E-Bike Hub Motors

- The Mechanics of Hub-Drive Motor

- Brushless DC Motor Explained

- Advantages of E-Bike Hubs

- Potential Issues With Hub Motors

- Comparing Hub Motors and Ordinary Motors

- Historical Overview of Hub Motors

- E-Bike Hub Maintenance Tips

- Future of Electric Bike Hubs

- Frequently Asked Questions

- Conclusion

Key Takeaways

- Hub-drive motors are built directly into the hub of the wheel for efficient power transmission.

- The type of hub motor chosen affects the overall experience and performance of the electric bike.

- The power source of hub-drive motors is crucial for the bike's drive system.

- Hub motors offer advantages such as lightweight construction, high top speeds, and extended battery life.

Understanding Electric Bike Hubs

Let's delve into understanding electric bike hubs, starting with the fact that hub-drive motors are integrated directly into the hub of the wheel, typically on the rear. This unique placement of the electric bike motor means it's right where the action is, spinning the wheel as it goes. The motor spins, creating the torque needed for acceleration. It's like being part of a team, where each component plays a key role in achieving our collective goal – a smoother, faster ride.

The motor controller plays the role of the brains, transforming the stator into an electromagnet, a marvel of science right inside the hub of our bikes. This is where things get really interesting. Some electric bike hubs employ geared hub motors that use a gear reduction system. It's like having a smart, efficient teammate who ensures we get the best possible performance from our bikes, optimizing speed and efficiency.

And let's not forget about the state-of-the-art features offered by companies like Magicycle. Their hubs employ advanced Lithium-ion battery technology, and exceptional heat resistance, ensuring a longer motor life. So, together, we're not just understanding electric bike hubs, we're becoming part of an exciting, forward-moving community.

Types of E-Bike Hub Motors

Diving into the world of E-Bike hub motors, we'll find a variety of types including geared hub motors, direct-drive hub motors, gearless hub motors, and mid-drive motors, all of which contribute uniquely to the overall performance and efficiency of our electric bikes.

Geared hub motors are lightweight and highly efficient. They rely on gears for speed reduction which makes them perfect for those of us who enjoy a smoother ride.

Direct-drive hub motors, on the other hand, are great for tackling heavy loads and long hills. They're simple, with just a single moving part, making them easy to maintain.

Now, if silence is what you're after, gearless hub motors deliver. They offer a smooth and quiet performance that's tough to beat.

Mid-drive motors sit near the bike's bottom bracket. They're the go-to choice for efficient climbing and offer a mechanical advantage that can't be ignored.

Understanding how electric bike hubs work, it's clear that the types of e-bike hub motors play a key role in the overall experience. We're able to choose a motor that best fits our lifestyle and cycling needs, ensuring our hub motors last and we continue to belong to the ever-growing community of e-bike enthusiasts.

The Mechanics of Hub-Drive Motor

Let's now turn our attention to the mechanics of hub-drive motors. In the upcoming discussion, we'll explore how these motors work, their power source, and the factors that influence their efficiency.

It's fascinating how these elements all come together to power our e-bikes.

Understanding Hub-Drive Motors

In the world of electric bikes, hub-drive motors hold a special place, being built directly into the hub of the wheel for efficient power transmission and better acceleration. You'll often find these motors on the rear wheel, connected to the stator through a gear reduction system. As we delve into understanding hub-drive motors, it's key to note their lightweight nature and high top speed capabilities.

Here's a simple table to break it down:

| Feature | Hub-Drive Motors | Other Motors |

|---|---|---|

| Position | Inside the hub | External |

| Weight | Lightweight | Heavier |

| Speed | Higher | Lower |

Hub Motor Power Source

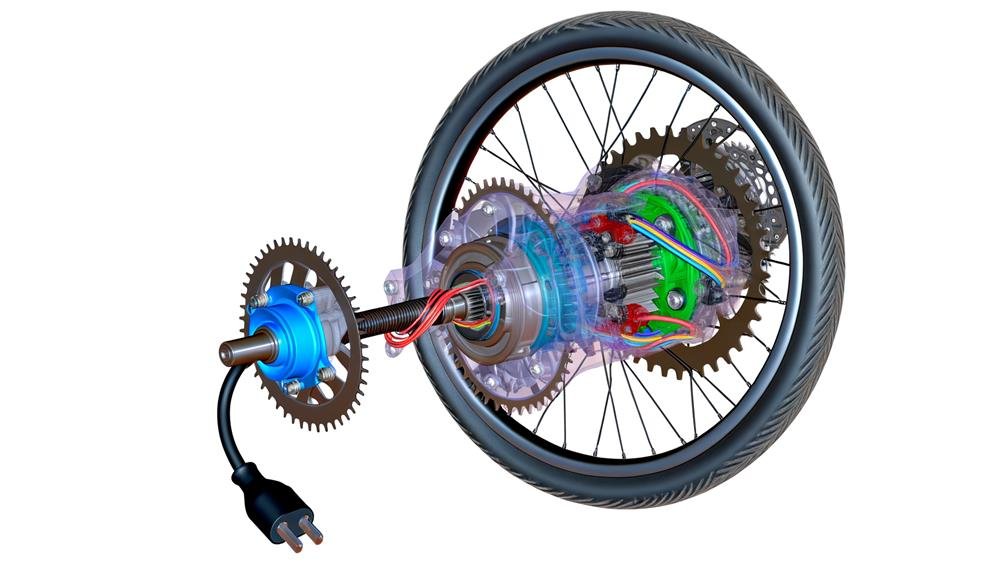

Having a grasp on the basic features of hub-drive motors, we now turn our attention to unraveling the mechanics of its power source.

Now, the power source of these electric motors is essentially the heart of your bike's drive system. It's where the magic happens!

- The motor controller converts the stator, a part with copper windings, into an electromagnet.

- This then interacts with the rotor's permanent magnets, generating torque. A higher torque means better acceleration for your bike.

- The gear reduction system allows the motor to turn at high speeds, maximizing efficiency and extending battery life.

This is how we roll, driven by the power within our bikes. Understanding this empowers us to truly belong in the world of electric biking.

Hub Motor Efficiency Factors

Now, we're diving into the factors that impact the efficiency of hub-drive motors, from gear reduction systems to motor placement and torque levels.

The first of the hub motor efficiency factors to consider is how the motor is built directly into the hub. The location, usually on the rear wheel, plays a crucial role in how do electric bike hubs work.

Gearing inside the hub reduces speed, affecting efficiency. The type of hub motor, such as the 52V geared hub motor, influences its performance.

Moreover, the torque level, like the 96Nm in the Magicycle Cruiser Pro, impacts efficiency.

Understanding these factors helps us appreciate the mechanics of the ever-evolving e-bike technology.

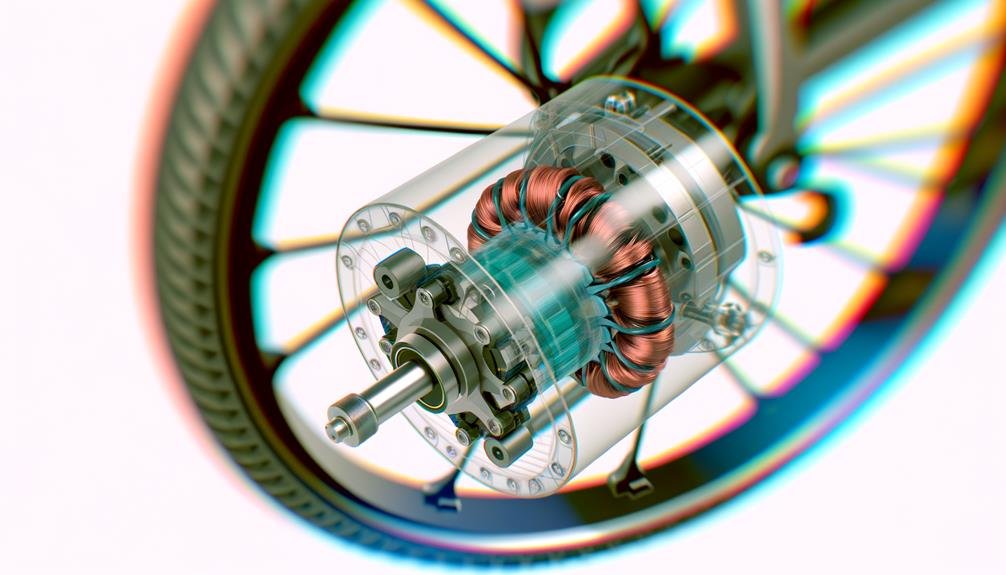

Brushless DC Motor Explained

Let's dive right into the workings of brushless DC motors, which are a key component in electric bikes due to their efficiency and superior performance at low speeds. Brushless DC motors are the heart and soul of electric bicycles, giving them the power and agility we so adore.

The motor system of these bikes is situated within the hub of the wheel, and it's truly a marvel of modern engineering. Now, to understand how it works:

- The motor replaces the traditional commutator and brushes with separate coils and an electronic circuit. This eliminates friction and energy wastage, making it more efficient.

- The electronic circuit switches the power on and off in these coils, creating forces that drive the motor to spin.

- Lastly, magnetic field sensors, or Hall-effect sensors, help the circuit determine which coils to activate to keep the motor spinning.

As we journey together in understanding the technology behind our beloved electric bikes, we become part of a unique community. We're not just riders, we're innovators, explorers of new frontiers in technology.

Advantages of E-Bike Hubs

Building on our understanding of the brushless DC motors in e-bikes, it's worth exploring the significant advantages offered by geared hub motors in these advanced bicycles. As part of our tribe of e-bike enthusiasts, you'll appreciate the value of a robust drive motor.

One of the main advantages of e-bike hubs is their lightweight nature. This makes your electric mountain biking adventures a breeze. The geared hub motor's gear reduction mechanism also allows for a higher top speed. You can zoom past traditional cyclists with ease and style.

Efficiency and extended battery life are other key benefits. A geared hub motor maximizes efficiency, providing a range of over 80 miles. This means fewer charging stops on your electric mountain journeys. It's a reliable companion, built to last with a separate pedal driving mechanism. This ensures longevity, so your e-bike is always ready for another adventure.

Potential Issues With Hub Motors

Despite the many advantages, there are potential issues with hub motors that e-bike riders should be aware of. As a fellow rider, I've had my fair share of experiences with these issues. They can impact the overall performance and efficiency of your e-bike.

- Brushless motor: This type of electric motor is often used in e-bikes for its efficiency and durability. However, they can overheat in high-load situations like climbing steep hills or carrying heavy cargo. This can reduce its lifespan and performance.

- Rear wheel: Hub motors are often installed in the rear wheel. This can cause an imbalance in weight distribution, affecting the bike's handling. It's also more challenging to change a flat tire on the rear wheel with a hub motor installed.

- Electric motors: They're complex devices. Any technical issue or malfunction could be complicated and costly to fix. This is particularly true for potential issues with hub motors, which are sealed within the wheel and thus difficult to access.

Comparing Hub Motors and Ordinary Motors

Let's move on to compare hub motors and ordinary motors.

We'll be looking at the key differences between them, examining the efficiency of hub motors and discussing the maintenance and lifespan aspects.

This comparison should give us a better understanding of why one might be a preferable choice over the other.

Hub Motors Versus Ordinary Motors

When comparing hub motors and ordinary motors, it's clear they each have their unique characteristics. Hub motors are built into the wheel's hub, while ordinary motors feature a rotating rotor inside a static ring-shaped permanent magnet. The distinction between hub motors versus ordinary motors presents a fascinating exploration into the types of electric machinery used in e-bikes.

Hub motors are lightweight and efficient, extending battery life. They provide higher top speed and stronger torque due to a gear reduction mechanism. Additionally, a separate pedal driving mechanism ensures durability and versatility across terrains.

In essence, the motor controller's decision between these two types of motors lays the foundation for the bike's performance. Ultimately, it's about finding a balance that suits your biking needs.

Efficiency of Hub Motors

Building on the unique characteristics of hub motors, we can further assess their efficiency, especially when compared to ordinary motors.

Unlike the traditional motors, hub motors are generally brushless, which eliminates friction, reducing energy wastage. This unique feature, along with the presence of permanent magnets, boosts their efficiency, making them a favorite in the '59 electric bike models and beyond.

The electronic circuit in the hub motor enhances efficiency at low speeds and is a game-changer for cyclists who prefer a slow, relaxed pace.

Also, these motors have magnetic field sensors that activate the right coils at the right time, ensuring the wheel spins smoothly and efficiently.

Maintenance and Lifespan Aspects

In discussing maintenance and lifespan aspects, it's clear that hub motors have a significant advantage over ordinary motors due to their design and minimal external components. This simplicity not only improves ride quality but also extends the lifespan of electric bike hubs.

- Hub motors, being built directly into the wheel hub, require less maintenance. There's no external moving parts to worry about.

- The lifespan of hub motors is potentially longer due to their design and reduced exposure to external elements.

- Unlike ordinary motors, hub motors don't need frequent lubrication or alignment checks.

Historical Overview of Hub Motors

Interestingly, hub motors hold the honor of being the first type of drive systems for bicycles to be patented. They were a marvel of electric propulsion, and over time, they've evolved from a basic concept to the advanced technology we now enjoy.

Originally, they were brushed motors, but manufacturers soon switched to brushless ones, a move that significantly improved their performance and lifespan. These motors typically sit in the middle of the wheel, hence the term 'mid drive'. They use a combination of electromagnets and rare Earth magnets to generate force. The electromagnets are made of copper windings, which create a magnetic field when an electric current passes through them.

Here's a simple table to illustrate the evolution of hub motors:

| Year | Type |

|---|---|

| Early years | Brushed Motors |

| Mid-period | Transition to Brushless Motors |

| Present | Mid Drive, Direct Drive with Copper Windings |

It's fascinating how far we've come, isn't it? The hub motors of today are a testament to human ingenuity and innovation. We've managed to take a simple concept and perfect it over time, creating a more efficient and reliable mode of transportation.

E-Bike Hub Maintenance Tips

Let's now turn our attention to some practical tips for maintaining your e-bike hub.

Keeping your e-bike hub clean and conducting regular check-ups can significantly extend its lifespan and performance.

We'll be discussing these points in detail, so expect to pick up some handy advice along the way.

Cleaning Your E-Bike Hub

Keeping your e-bike hub clean and well-maintained isn't just about aesthetics; it's crucial for its performance and longevity. Just like taking care of the lithium battery and adhering to the speed limit, maintaining your hub is part of the e-bike journey.

Here are three simple steps I follow:

- I wipe down the hub and spokes with a damp cloth regularly. This helps keep the grime off and my disc brakes functioning optimally.

- I use a gentle brush to dislodge any debris hidden in the nooks.

- I keep an eye out for signs of wear or damage. If I spot any, I address them immediately to ensure my Pedal Assist system stays in top shape.

Regular Hub Check-ups

Regular check-ups on your e-bike hub can significantly extend its life and enhance performance. You're part of the e-bike community now, and understanding how do electric bike hubs work is essential.

Regular hub check-ups involve looking for signs of wear or damage to the hub motor casing and wiring. I make sure it's securely fastened and there are no loose components. Cleaning is also vital to maintain optimal electric propulsion.

I test its functionality by engaging the assist and listening for unusual noises or vibrations. Monitoring the hub motor's temperature during use is key, especially for mid drives, to prevent overheating and potential damage.

Regular maintenance will keep you in the saddle for longer.

Future of Electric Bike Hubs

Looking ahead, the future of electric bike hubs holds great promise, with advancements in technology aiming to enhance efficiency, performance, and rider experience even further.

The way we understand how do electric bike hubs work is set to change, and I'm thrilled to map out what we can expect.

- Increased Efficiency: Future electric bike hubs are likely to leverage even more advanced electric propulsion technologies. This could result in higher acceleration and an increase in top speeds, making your rides more exhilarating than ever.

- Extended Range: With advancements in battery technology, we can expect electric bikes to travel even longer distances without needing a recharge. This means more freedom to explore and less worry about battery life.

- Enhanced Rider Experience: The next generation of electric bikes will likely incorporate more user-friendly features. Think high-quality LCD displays, more responsive braking systems, and even smarter heat resistance mechanisms to ensure your bike's motor life is extended.

Frequently Asked Questions

How Does Hub Drive Work?

I'll explain it simply: hub drives work by a motor in the wheel's hub generating power. This causes the wheel to spin, propelling me forward. Gear mechanisms inside help boost efficiency and torque. It's pretty cool!

What Is the Life Expectancy of the Ebike Hub Motor?

Like a well-oiled machine, my ebike's hub motor's lifespan depends on care and usage. With regular maintenance, it's likely to last several thousand miles. However, riding conditions and load can impact its longevity.

Are Ebike Hub Motors AC or Dc?

E-bike hub motors are DC, or direct current, motors. They're part of the DC motor family, lacking a brush mechanism for excitation in windings, making them efficient, especially at lower speeds.

What Are the Different Types of Electric Hubs?

Electric bike hubs come in different types – geared, direct-drive, gearless, and mid-drive. Each type has unique features catering to various weight, power, terrain, and riding conditions, offering a tailored riding experience.

Conclusion

In a nutshell, e-bike hubs, particularly hub-drive motors, are a game changer in the cycling world. They're not only powerful and efficient but also extend battery life.

They're a piece of cake to maintain and offer a smoother ride. As technology progresses, I believe we're only scratching the surface of what these motors can offer.

So, if you're considering an e-bike, a hub motor might just hit the nail on the head for you.

Charles Miller is a veteran bike enthusiast with over 12 years of experience dealing with bikes as a mechanic. Despite immense love and expertise for his Tacoma, he rides his Trek Ebike more. Anytime you meet him, you’ll either hear him talking about Bikes, or writing about all things bikes and cars on this blog.

More Posts