Charles Miller is a veteran bike enthusiast with over 12 years of experience dealing with bikes as a mechanic. Despite immense love and expertise for...

Peeling back the layers of an ebike battery is like opening a complex, electrified puzzle box. As a professional, I've spent years studying and understanding the intricate details that go into crafting these powerhouses.

Essentially, they're made up of lithium-ion cells – often 18650 cells – wired together to create the desired voltage. But it's not as simple as stringing them together. You've got to consider the capacity and power capabilities of different brands and types, not to mention the essential components like a battery management system, a spot welder, and a myriad of other tools.

Now, wouldn't you like to know more about how we assemble these electrifying enigmas?

- Key Takeaways

- Understanding Ebike Battery Components

- Choosing the Right Battery Size

- Steps for Assembling Battery Cells

- Importance of Equal Voltage Cells

- Process of Hot Gluing and Welding

- Preparing Charging and Discharging Connectors

- Connection of Wires to the BMS

- Wrapping the Battery With Foam

- Finishing Touches: Adding Heat Shrink

- Frequently Asked Questions

- Conclusion

Key Takeaways

- Ebike batteries are made up of lithium-ion cells, typically 18650 cells, wired together.

- The capacity and power capabilities of the battery cells should be considered when assembling the battery.

- A Battery Management System (BMS) is necessary to protect the battery during charging and discharging.

- Spot welding is used to connect the battery cells, and other tools like nickel strip, voltmeter, soldering iron, and heat shrink tube are required for assembly.

Understanding Ebike Battery Components

Let's dive into the components of an Ebike battery, starting with the commonly used cylindrical 18650 lithium-ion cells known for their energy density and power output. As DIY enthusiasts, we recognize the power of creating our own electric bicycle lithium battery. The heart of our DIY lithium battery is these little powerhouses – the battery cells. When we build our own ebike, we create a unity of these lithium-ion cells, each contributing to the overall strength of our ebike battery pack.

Choosing the right cell groups based on capacity and power requirements is crucial. Brands like Panasonic, Sanyo, and Samsung offer different options, and the choice hinges on our individual ebike needs. Alongside these cells, a Battery Management System (BMS) watches over our battery, protecting it during charging and discharging.

Now, assembling these components requires specific tools. A spot welder comes into play, connecting our battery cells. Other crucial components include nickel strip, a voltmeter, a soldering iron, and heat shrink tube. Our DIY electric bicycle isn't just a project, it's a testament to our skills, and every part is a piece of that story.

Join me, let's build together.

Choosing the Right Battery Size

Moving on to our next important step, choosing the right battery size, we need to consider the voltage and capacity requirements of our electric bike.

As part of the ebike community, we're all in this DIY ebike adventure together.

When choosing the right battery size, it's crucial to understand the power needs of your ebike. This involves selecting the correct lithium cells, which come in different brands like Panasonic, Sanyo, and Samsung. These brands offer varying capacities and continuous current capabilities:

- Capacity dictates how long your battery can power your ebike before needing a recharge.

- The continuous current rating defines the maximum discharge current that the battery can handle without overheating.

Given the high voltage requirements of some ebikes, you might need to connect multiple cells in parallel to meet the power demands. It's also essential to match the Battery Management System (BMS) voltage and discharge current rating with your battery's specifications.

In building a strong electric bicycle battery, remember:

- Use 100% nickel strip for connections

- Use a heat shrink tube for safety

- Use a spot welder to assemble the battery cells

Let's keep powering forward on our DIY ebike journey!

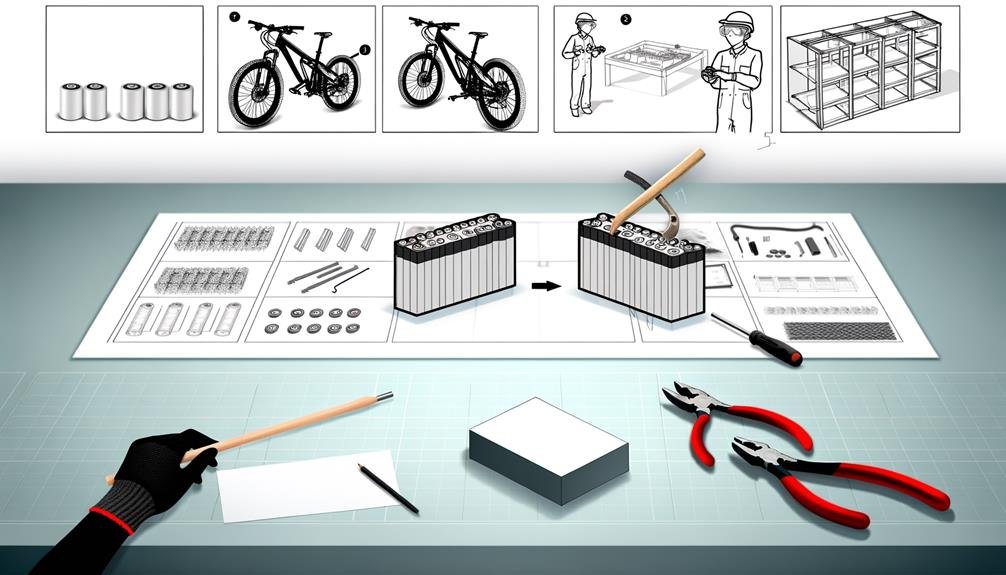

Steps for Assembling Battery Cells

Diving into the assembly of battery cells, we first need to gather the necessary tools and components. We're all in this together, so let's start by understanding our tools. Spot welders, especially, play a pivotal role in assembling ebike batteries.

We begin by arranging our cells in series, a task that requires precision and attention to detail. Each cell group then needs to be secured, ensuring they're stable for the next step. This is where our spot welders come into play, with their welding arms carefully connecting each cell, both positive and negative ends, in a meticulous process known as Spot Welding.

Once we've connected all cells, it's time to protect our hard work. We use heat shrink tubing to cover the battery packs, providing an extra layer of safety and durability. It's a satisfying moment, seeing our assembled battery cells, ready to power our ebikes.

Through these steps, we not only assemble ebike batteries but also create a sense of accomplishment and belonging. So remember, each time you ride an ebike, it's not just a battery powering it, but a community of dedicated individuals who've worked together to assemble each cell.

Importance of Equal Voltage Cells

Let's shift our focus to the importance of equal voltage cells in ebike batteries.

It's crucial to understand how balanced cells contribute to the battery's overall performance and longevity.

We'll also discuss the possible repercussions of using mismatched voltage cells, emphasizing the need for balance.

Ensuring Cell Balance

When it comes to ebike batteries, ensuring cell balance is absolutely vital to maintain equal voltage among the cells in the battery pack. This balance is especially important for a new ebike, as it optimizes battery performance and lifespan.

To ensure your ebike's cells are balanced:

- Monitor your cells regularly:

- Use a Battery Management System to keep track of each cell's voltage.

- Ensure no cell is fully charged while others are at lower voltage.

- Prioritize high quality cells:

- Higher capacity cells provide longer rides.

- The number of cells, from positive to negative, should be balanced.

Consequences of Unequal Voltage

While we've emphasized the importance of maintaining cell balance in ebike batteries, it's crucial to understand the negative implications of unequal voltage among these cells. When ebike batteries are made, achieving equal voltage across cells is vital for optimal performance. Unequal voltage can lead to consequences such as reduced battery life and potential damage.

In a high power discharge scenario, a cell with lower voltage can become over-discharged, causing irreversible damage. In a charge scenario, a cell with higher voltage can overcharge, leading to overheating or even explosion.

Whether cells are connected in series or parallel, maintaining equal voltage across all cells is key to ensuring your ebike battery's longevity and safety. So, it's more than just belonging – it's about sustaining our ebike journey.

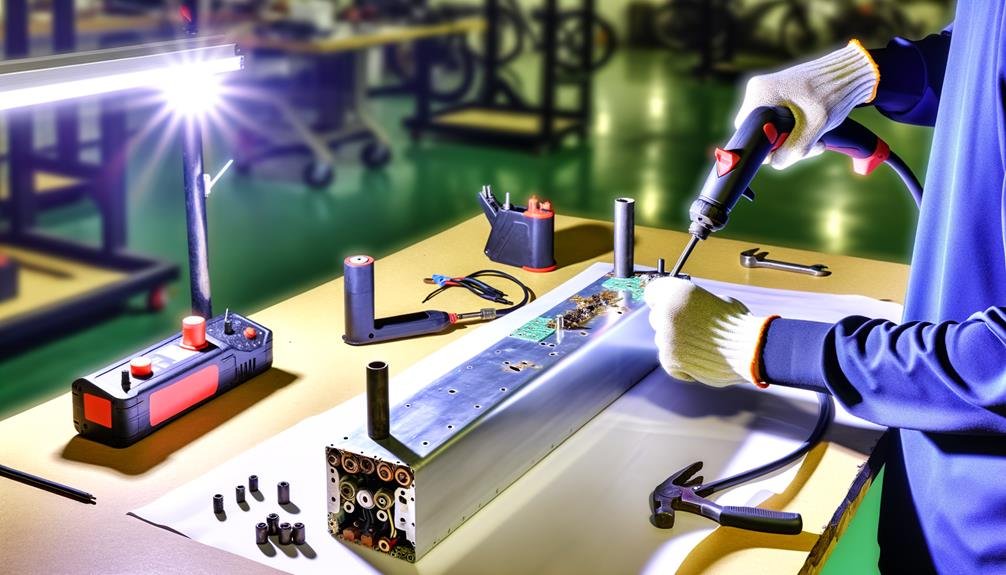

Process of Hot Gluing and Welding

Diving right into the heart of ebike battery assembly, we use a hot glue gun to firmly secure components such as wires and connectors, setting the stage for the crucial step of spot welding. In the process of Hot Gluing, each component is carefully hot glued into place, creating a reliable foundation for the rest of the assembly.

Here's a glimpse into the steps involved:

- Hot Gluing

- The first step involves hot gluing the components.

- It's a method I always use when designing and building ebike batteries.

- Spot Welding

- The second step is to use a spot welder to weld the cells together.

- Each cell receives not one weld but two, at the first and second weld points.

This process ensures that the cells are securely connected and ready for the road. Spot welding is essential because it prevents excessive heat generation, which could potentially damage the cells. It's a method I've come to trust, and it's a staple in the ebike community. If you're considering diving into the world of ebike battery assembly, investing in a spot welder could be a game-changer for you.

Preparing Charging and Discharging Connectors

Before we dive into the nitty-gritty of preparing charging and discharging connectors, it's crucial to ensure that all safety precautions are firmly in place. We're dealing with sensitive components here, such as Lithium Panasonic 18650pf cells, which require a good deal of care.

When it comes to preparing connectors, we need to ensure that we use appropriate voltage and current-rated ones. These must match the specifications of the battery management system for efficient power flow. It's also essential to prioritize spot welding for connecting the cells together. This minimizes heat damage and ensures secure connections.

Now, take a gander at this table:

| Component | Purpose | Material |

|---|---|---|

| Nickel strips | Connect cells | Tested for authenticity |

| Heat shrink | Protects assembly | Durable plastic |

| Sense wires | Check cell voltages | Copper |

This table outlines some key parts of our ebike batteries pack. Nickel strips connect our parallel groups of cells, while heat shrink protects our pack. Sense wires, according to our wiring diagram, help us to monitor cell voltages.

In essence, preparing charging and discharging connectors is a critical step in ensuring our ebike batteries are safe, efficient, and ready to power our journeys.

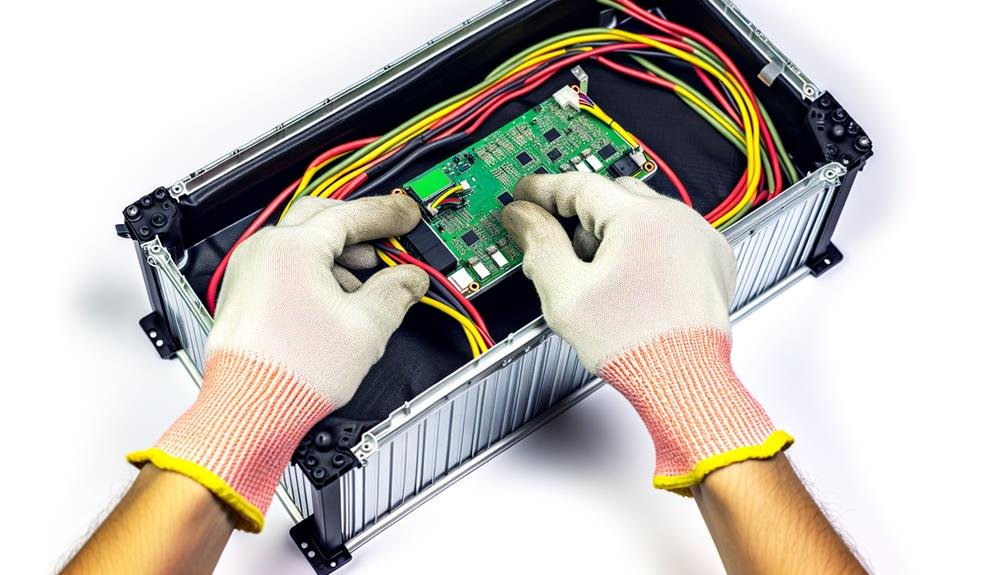

Connection of Wires to the BMS

Moving on to the connection of wires to the BMS, it's crucial to remember that this step plays an integral part in the overall safety and performance of your ebike battery. The first step is to make sure you're following the Privacy Policy and guidelines set out by the BMS manufacturer.

The use of proper insulation tools like a heat gun and materials like nickel plated steel wire is essential. This is because they provide a certain amount of resistance to the heat generated during the connection process.

Now, let's get into the nitty gritty of how these wires are connected together:

- The common types of connections include series and parallel.

- Series: The positive terminal of one cell is connected to the negative terminal of the next. This is done to increase the voltage.

- Parallel: The positive terminals of all cells are connected together, and the same goes for the negative terminals. This is done to increase the capacity.

Wrapping the Battery With Foam

After ensuring proper wire connections, it's equally crucial to focus on the protective measure of wrapping the battery with foam. This isn't just a casual precaution; it's an essential safety step that keeps everything secure inside an ebike battery.

Now, let's get our hands on a piece of foam. I opt for a dense, protective layer that fits snugly around the perimeter of my pack. It's not just about making sure it fits; it's about creating a buffer for those Samsung 26F cells we've carefully arranged in parallel. You see, these cells need to be shielded from impact and vibration, and that's exactly what wrapping the battery with foam achieves.

It's also crucial to remember that you'll need to wire correctly, and for that, I've used 16 awg. It's sturdy, reliable, and works well with the foam.

Finishing Touches: Adding Heat Shrink

Once we've securely wrapped the battery with foam, it's time to add the finishing touch: the heat shrink tube. This process involves choosing the right size heat shrink, applying it properly, and adding just enough heat without damaging the cells from getting overheated.

The first step involves choosing the right heat shrink. The sizes of heat shrink vary, and it's crucial to select the right one for a neat and secure wrap around your battery. Here are a few things to consider:

- Small heat shrink vs large diameter heat shrink tube

- Small heat shrink is perfect for individual cells or small parts of the battery.

- A large diameter heat shrink tube is typically used to cover the whole battery pack.

The next part involves applying the heat to the tube. You have to be cautious to avoid heating the tube too much. Remember, the goal is to shrink the tube securely around the battery, not to overheat the cells.

Joining this DIY ebike community means you're part of a group that values safety and efficiency. So let's get those finishing touches right and ensure our batteries last as long as possible.

Frequently Asked Questions

What Are Ebike Batteries Made Of?

Ebike batteries are primarily made of lithium-ion cells. They're combined with a battery management system for safety, and other components like nickel strips, foam sheets, and wires. It's quite a technical but exciting process!

Is It Cheaper to Build Your Own Ebike Battery?

Yes, it's generally cheaper to build your own ebike battery. I've found that buying lithium cells in bulk and assembling them myself saves me about 50% compared to retail prices. It's a fun and rewarding project too!

What's Inside an Ebike Battery?

Inside an ebike battery, you'll find lithium-ion cells, typically 18650 cells. It also contains a battery management system for monitoring. Nickel strips connect the cells, and a variety of wires and connectors are used.

What Battery Cells Are Used in Ebikes?

Ebike batteries often use lithium-ion cells, like the cylindrical 18650 cells. They've got great energy density and performance. Different types, like Panasonic 18650pf or Samsung 26F cells, suit various ebike needs.

Conclusion

Crafting an ebike battery is a lot like baking a complex dessert. Each ingredient must be precise, like the perfect voltage, and the process followed carefully. A single misstep, like an uneven voltage, can turn your masterpiece into a disaster.

But when done right, you've got a powerful, efficient dynamo. It's a laborious task, but as I've found, the satisfaction of powering your own ride is a sweet reward, much like savoring a well-baked dessert.

Charles Miller is a veteran bike enthusiast with over 12 years of experience dealing with bikes as a mechanic. Despite immense love and expertise for his Tacoma, he rides his Trek Ebike more. Anytime you meet him, you’ll either hear him talking about Bikes, or writing about all things bikes and cars on this blog.

More Posts